PROBLEM

The global subsea steel pipeline network is >150,000 km long. The proportion that will ultimately require removal is uncertain and contested. However, this has been getting much clearer in recent years due to changes in community & regulator expectations.

O&G Operators in Thailand, Australia & the UK are facing increasing pressure from their Government Regulators to remove 100% of subsea steel pipelines, with others in the OECD likely to follow. Operators & Governments are also structurally incentivised to reduce costs, without impacting on the environment or safety. There is $0 revenue for Operators, plus 40% to 70% of all costs are re-couped by Tax Credits.

The Subsea Contracting market is capital intensive, entrenched & has a laser focus on ROC for current assets. Tier1 Subsea Contractors don’t have an incentive to offer anything but the the same high day rate vessels they own & operate and were used to install all of these pipelines via their 3 x industry status quo technologies of S-Lay, R-Lay & J-Lay, that have been established for >30 years. We estimate the total Potential Addressable Market (PAM) for subsea steel pipeline removal across Australia, UK & USA using these status quo technologies to be A$41B by 2040. New solutions are required to reduce environmental impacts and costs - but are unlikely to be developed by the incumbents.

SOLUTION (X-LAY)

Restore Subsea is developing a suite of IP & Patents (granted UK, pending in Australian & USA) for a range of new pipeline removal solutions we have called X-Lay. We have completed our "Technology Demonstrator Phase" from Q3 2020 to Q2 2025, ie "sufficiently proven that the underpinning science delivers a solution that is both a fit and superior to alternatives to a significant targetet consumer problem". Our next key goal is to complete our "Commercial Demonstrator Phase" before 2H 2026, ie "successfully demonstrate that X-Lay has superior commercial value to known alternatives and is offered in a business Model that is accepted by the market and is repeatable and scalable".

This will involve DNV validation, with further R&D and pipeline bend testing to pre-qualify our proprietary solutions in readiness for Operator Invitations to Bid (ITB) to Subsea Contractors for various looming pipeline removal projects requiring offshore execution from 2029 to 2030. Our plan is to combine our IP with advanced pipeline strain management, plus further R&D and lab testing of various pipeline types and sizes.

Our ultimate goal is to license X-Lay to Tier 2 Subsea Contractor(s) to enable much lower day rate vessels to remove all subsea steel pipelines at much higher productivity levels; in 160' to 400' joint lengths vs 40' lengths as per Tier 1 S-Lay vessels. This will result in >50% cost savings to the Operators and also importantly these savings flow through to Governments who provide major tax credits. The successful development of X-Lay will therefore ultimately result in much better outcomes for our customers, partners, governments and ultimately the subsea environment !

We estimate that X-Lay's Share of Market (SOM) across Australia, UK & USA to be A$32B of the A$41B PAM by 2040. We further estimate that by 2040 X-Lay could generate >A$6B of cost savings to Operators, resulting in >A$4B of tax credit reductions from Australian & UK Governments, plus significant royalty & licensing fees flowing to Restore Subsea. As with the introduction of any disruptive technology, investing in X-Lay will result in continued generation of cost savings to Operators, tax credit reductions from Governments and better subsea environmental outcomes well beyond 2040.

X-LAY (USE CASE 1 - Gulf of thailand)

Provided engineering input to a Contractor’s bid to an Operator in Thailand in 2020. The Contractor provided the Operator with a conforming bid using a DP2 S-Lay vessel, plus an alternate bid based on our X-Lay solution - using a much lower day rate DP2 CSV.

The pipeline removal scope was as follows:

- 60 Subsea Carbon Steel Pipelines x 200km total length, up to 80m WD.

- Pipe 8” to 24” OD.

- Pipe Wall Thickness ½” to ¾”. Concrete Coating 1”.

- Coatings varied. Concrete coated, FBE coated and PPL coated

The alternate bid could retrieve all the wet pipelines to shore in 160', rather than 40' joint lengths, resulting in major cost saving vs the base bid. However, it was not closely considered by the Operator, due to X-Lay not being pre-qualified.

X-LAY (USE CASE 2 - COMBINED STEEL PL + FLEX LAY REMOVAL)

Provided engineering input to a Contractor’s bid to an Operator in Australia in 2023. The Contractor provided them with a conforming bid using a DP2 CSV, to cut up and retrieve the 9km of pipeline subsea. A separate bid was provided by others to remove the flexible flowlines and umbilicals. The Contractor also provided the Operator with an alternate bid, based on our X-Lay approach. This was to retrieve both the circa 150km of flexible flowline and umbilicals, plus 9km of steel pipelines with the same DP2 CSV.

The subsea removal scope was as follows:

- 12" Subsea SS 316L internally lined Steel Pipelines x 9km total length, up to 160m WD.

- Pipe 12” , c/w 2" piggyback.

- Pipe Wall Thickness ½” to ¾”.

- Coatings 3-layer FBE/PE.

- 53 km of Flexible Flowlines.

- 90 km of Umbilicals.

- 25 x Seabead structures, etc..

The alternate bid could retrieve all 9km of steel pipeline without exposing the inside of each pipe joint to the ocean environment, with significant cost savings resulting from 1 x instead of 2 x mobilisations. However, it was not closely considered by the Operator , due to X-Lay not being pre-qualified.

X-LAY (USE CASE 3 - COMBINED WITH RAPID PIPE COnnectors)

Joined forces with Cladtek in June 2024, to present and market a collaborative offering that we described as "Recovering the Past & Facilitating the Future".

Cladtek has completed various Feasibility Studies over the years for a range of lay systems that enable the installation of "Rapid Pipe" - a mechanically connected pipe system. Operators can have Rapid Pipe installed and removed from a wide range of Tier 2 Contractor CSV's and from Semi Sub Drilling Rigs. Rapid Pipe is much lower cost than the well established Tier 1 Contractor welded solutions in many applications, plus it can also be easily retrieved and re-used, providing much better environmental outcomes.

Rapid Pipe and it's associated installation systems have been undergoing extensive technology qualifications with clients such as Petrobras, ExxonMobil & Petronas. These are particularly extensive as these pipelines of the future will be transporting O&G, some in >2,000m WD at high temperatures and pressures, plus with highly corrosive fluids for >30 years.

One of these systems as shown is a semi J-Lay type one, that installs rapid pipe in 160' long joints on Tier2 Contractor CSV's. X-Lay can enable this same system to also be used for the reverse removal of very large diameter and/or deepwater welded pipelines in 160' long joints in the same campaign.

X-LAY (USE CASE 4 - XXXL deck length CSV)

In addition to Use Case 3, Cladtek's Rapid Pipe system can be used on the longest deck DP2 CSVs currently available globally. These have been recently developed for the installation of offshore wind farms, which given the recent changes in policy direction on offshore wind, maybe on shaky ground for future demand in 2030. Rapid Pipe can be installed & re-used in 400' joints using such vessels.

X-Lay enables the same system to also be used for the reverse removal of very large diameter and/or deep-water welded pipelines in 400' long joints. This was also presented at D&A AUS June 2024, as another options consistent with "Recovering the Past & Facilitating the Future".

X-LAY (USE CASE 5 - ANCHORED BARGE)

Joined forces with Cladtek again for SPE D&A APAC in KL Dec 2024, to present a similar theme of "Recovering the Past & Facilitating the Future". This time we focused more on aiming to appeal to Operators and/or Contractors in SEA who may want to be a 1st mover in SEA for X-Lay, that could then also be applied in Australia offshore circa 2030.

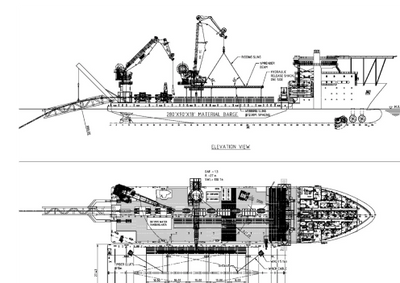

We showed how the same X-Lay system for cutting and retrieving 160' long joints could 1st be deployed on a HUC Barge with 8 point mooring (as shown here), for the removal of the forecast 275km of pipelines in <15m WD , before being transferred onto a DP2 CSV, to remove the remaining 600km of pipelines. This forecast total cost savings vs status quo solutions was >70%.

If a Cladtek Rapid Pipe approach is taken, then the same X-Lay type system could also be used to install the connected Pipelines of the Future...through the 2030’s and beyond.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.